PROJECT MANAGEMENT

Over the years, Special Piping Materials has developed an enviable reputation for project management for the oil & gas, petrochemical, nuclear and other heavy industries. This includes an impressive history of managing and supplying packages to engineering contractors and major clients.

Clients who choose Special Piping Materials as their project management partner can be secure in the knowledge that all our projects are handled by a dedicated and experienced team. Each team is hand-picked for each specific project, based on their prior expertise, skills and familiarity with that project type, the materials being selected, and the products required.

The many years of experience that we have means that there is always someone who has the ability to carry a project forward.

What is project management?

What makes something a ‘project’ within our industry is when we receive a large-scale order of items with different specifications and a varying array of logistics to coordinate (marking, packing, handling, expediting, shipping quality control) which we then follow exactly to our clients’ requirements.

We work with our trusted supply chains to ensure that the materials and goods are quality assured, delivered on time to where they need to be, with all the required documentation and details.

Some of our customer requirements can include:

• Market awareness

• Strict technical competency

• Fast-paced deadlines

• Complex material packages

• Approved manufacturer lists

• Strict communication channels

Taking responsibility for project management

We manage each of our projects in a personal and bespoke way.

Our teams fit into our client’s project management teams. They follow their structure and adhere to their unique way of doing things to make the process easier and more efficient.

Each project is allocated a dedicated team of SPM personnel who look after the details from initial assessment and quotation, to delivery of materials and the final submission of document dossier.

Each of our clients naturally want their supply chain to operate in a particular way and part of our high-quality project management service is that we ensure this happens. We adapt our contractual and technical terms and procedures to provide a custom-service for each of our customers.

Typically, projects are made up of many different items all of different materials, product types, (seamless, flanges, welded, couplings etc) which means that all these specialist items have to be sourced from expert mills, often across the globe.

Special Piping Materials works to consolidate these goods and bring the project together as one. This involves creating master flow charts that bring together different timescales and procedures so that it can be managed and understood in an accessible way.

Part of project management can also see us storing goods securely in our warehouses around the globe before they are distributed to where they need to be. We can also work to ship items directly from source to destination, ensuring there are no delays to a project that often has numerous and complex moving parts.

Our teams work to fit seamlessly into our customer’s team, and often use their internal e-portals and digital systems to process the required paperwork. Their experience in this area means that they are able to quickly get up to speed with how these operate.

Dedicated Resources

We have dedicated and fully computerised project management systems with electronic logs that detail every aspect of each project so nothing can go amiss.

Special Piping Materials personnel regularly visit each manufacturer to establish lists of key contacts who are responsible for the various different disciplines that are often required within a project, such as production, documentation and commercial negotiations.

Reporting Systems

Special Piping Materials’ manufacturing partners regularly update us on the exact status of every product ordered from them.

Visits (either in person, or virtually) to each mill take place at regular intervals to ensure that contracts are completed as promised in terms of material quality, documentation and delivery schedule.

Documentation

Some of our customer requirements can include:

• VDRL / SDR

• Quality Plan / Inspection Test Plan

• WPS/PQR

• Non-Destruction Procedures and certification

• Heat Treatment Procedures and certification

• Production Schedule

• 3.1 MTC

• Vendor Data Books

Project History

Special Piping Materials has a long history of project management and we have worked on a number of high-profile projects, such as:

• OSX II

• BP Quad 204

• Cidade de Ilhabela

• Shell Stones

• Apache North Sea

• Shell Prelude

• BP Angola

• Chevron Gorgon

• Exxon Mobil

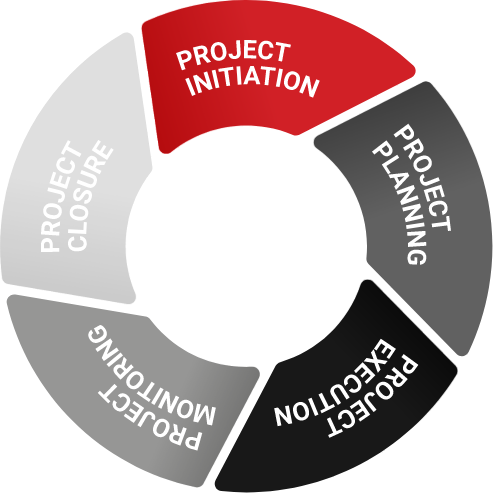

Project Management Life Cycle

While every project that we manage is treated in a personalised way, we do follow a project management ‘life cycle’ routine that ensures that no detail is missed.

It means that our teams can work in a structured and methodical way and makes our clients feel secure in the knowledge that every aspect of a project is in hand.

Throughout this process we stay in close contact with our clients, communicating with them on a regular basis so that expectations are managed and met.

We have found that breaking down a project into five ‘life cycle’ phases works well:

1. Project initiation

This crucial first phase is where a project’s value and feasibility are evaluated, along with its goals, timeline and costs. We can then start the conversation with our client about how it would be managed, and we can start allocating appropriate team members to it who have the most relevant experience.

2. Project Planning

Once a project is given the go-ahead then it is time to start the planning process. A sold plan is created with a view on timescales, budget, resources, financing and product procurement. This allows our team to anticipate any possible obstacles and mitigate them before they arise.

3. Project Execution

This is when the ‘magic’ happens, and a project is brought to life! The team leader allocates resources and responsibilities to team members who then work hard to stay focused and coordinated. A solid project planning process pays dividends when it comes to project execution!

4. Project Monitoring

This phase happens simultaneously with the project execution phase. As the project progresses it is continuously monitored to ensure that key performance indicators (KPIs) are met.

5. Project Closure

Once every KPI is met and materials and products are delivered to the satisfaction of our clients, a project is taken to completion. As a final step, a project is evaluated, and the final documentation and dossier are delivered. Evaluation is a vital step in any project as it allows our team to continually improve and make every subsequent project even more successful than the last.

GET IN TOUCH WITH OUR TEAMS IN ONE OF OUR GLOBAL OFFICES TODAY

To find out how we can work seamlessly alongside your specialists and help to manage your projects and developments

England

Scotland

USA

Brazil

Singapore

Dubai

Oman

Australia

Website Design by Numagoo

Português do Brasil

Português do Brasil